- You are here:

- Home >

- Products >

- Rail Weighbridge

ZGU-100-DG Chinese Rail weighbridges are purpose built to weigh rail locomotives and rail wagons. The rail weighers are designed and built to accept the appropriate rail gauge. All rail weighbridges are designed by experienced civil and mechanical engineers.

As pioneers in dynamic weighing of rail vehicles,SILVERLAKE now have the largest number of in-motion weighing systems in operation worldwide. From simple static systems which weigh single rail cars to bespoke dynamic systems for weighing full trains in motion, all of our rail weighing scales are extremely durable and able to operate in the harshest conditions

A custom-built software package can be used to aid filling rail wagons, or for calculating shims in rail locomotive suspensioning.

SILVERLAKE can also supply the complete range of weighbridge hardware and weighbridge software solutions for any site. Hardware option includes boom gates, electronic identification systems, traffic control lights, driver control stations, personal computers, printers, radio modems, remote displays, and more.

- Overview

- Specifications

- Accessories

- Literature

ZGU-100-DG Chinese Rail weighbridges

SL-ZGUŌĆö100ŌĆöDG automatic rail-weighbridge’╝īis a kind of the train is controlled by a computer weighing equipment. Four stalk Goods trains, oilcan trains that be applicable to the standard gauge carry on the whole train dynamic state's weighŃĆéThis product has a high degree of automation, wide application range, simple operation, reliable performance, the weighing accuracy and feature rich, long running stability is good.This product won the national quality gold medal.

This product is composed of base, weighing transducer, load device, weighing instrument, printers and other devices’╝īweighing instrument will be treated as weighing sensor output signal of vehicle load’╝īautomatically convert quality values’╝īcalculate the weight of the vehicleŃĆéSpecial weighing instrument meter adopts imported IC design form secondary instrument control system’╝ømechanical loading device using thin integral steel structure’╝īcharacteristic is more holistic, simple installation, easy maintenance’╝øautomatic rail weighbridge using digital sensor replaces the analog sensor’╝īsensor output is a digital signal’╝īcomputer directly read operations of the digital signal of the sensorŃĆéAdopting digital sensor features below’╝Ü1.higher precision’╝ø2.strong anti-interference ability’╝ø3.long transmission distance and no attenuation’╝ītransmission distance can reach 1000 m’╝ø4.can determine the direction to compensate’╝ø5.accurate judgment fault’╝ø6.convenient debugging calibration’╝ø7.replace the sensor without calibration’╝ø8.to prevent cheating in remote.

(Main technique parameter and function)

The minimum weighing automatic rail weighbridge to 18 t, the biggest weighing 100 tŃĆé

The rail of the weighing-machine is long 3.6 metersŃĆé

Two-way automatic bogie dynamic weighing method for measuring, even hanging dynamic metering or not even hang humping dynamic measurementŃĆé

Train measurement speed range:3kmh TO 18kmh’╝ī(Not measured by weighing apparatus maximum speed’╝Ü25kmh

Error margin and accuracy’╝Ü

Match the nation examination rules JJG234-2012 Automatic rail-weighbridges of correspond the item.

aŃĆü’╝łAccuracy of automatic rail weighbridge is divided into four

levels: 0.2, 0.5, level 1 and level 2ŃĆéMy company's

automatic rail weighbridge usually adopt level 1’╝ē

bŃĆü(Permissible error table)’╝Ü

| (The accuracy level) | (Verification index value) | n=Max,e (Verification points degree) | |

| (Max) | (Min) | ||

| 0.2 | above 50 | 1000 | 5000 |

| 0.5 | above 100 | 500 | 2500 |

| 1 | above 200 | 250 | 1250 |

| 2 | above 500 | 100 | 600 |

cŃĆü(Accuracy)

Equipment increase or decrease the 20 kg weight, value should be not less than 10 kg of changeŃĆé

The total power consume’╝ÜABOVE 500W

(The work condition)’╝Ü

(Measurement of the vehicle must conform to the requirements of the railway’╝īweight is more than 18 t and less than 100 t’╝łspecial circumstances can reach 150 t’╝ē’╝ītrack width is 1435 mm axles truck)

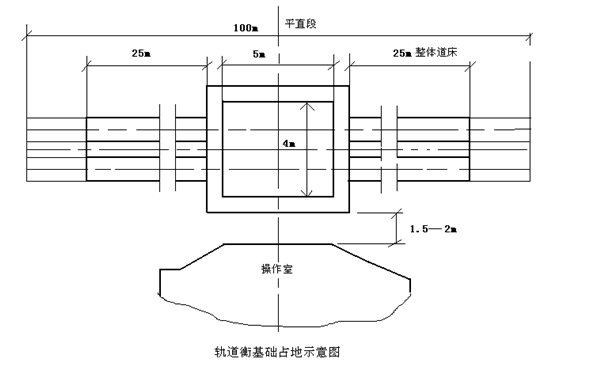

(The machine part installs in the pit ,The equipments pit both ends should have the certain long straight and even orbit.)

’╝łSensor normal work temperature’╝ē’╝Ü0C---60CŃĆé

The environment of the Calculate building is at the request of match the usage of the Computer.’╝ē

’╝łPower voltage’╝ē’╝Ü220V┬▒10%’╝ī50┬▒2HZŃĆé

(The equipments keeps off the strong electromagnetism interference, keeping off the erodent gas.)

(The control room has to connecting a ground goodly, electric resistance small in 4╬®.)

(The product constitute and structure characteristics)

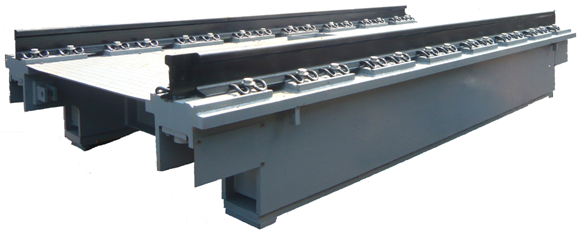

(This product is from the machine part, weigh Sensor and weigh the displaying instrument, printer composing. Each part of main function and characteristicses are as follows.)

4-1 Machine part)

(The machine part is use to load the vehicle’╝īthe machine part from main beam’╝īweigh sensor to link up the system’╝īa system of horizontal limit’╝īlengthways Limit’╝īthe protection cover plank etc. constitute( see the diagram)ŃĆé)

(The main beam uses profiled bar welding ’╝īit cuts to face trunk’╝īhaving the enough strengthŃĆéBuild the steel rail on the main beam’╝īprovide to load the vehicle to go throughŃĆé)

(The machine part passes to Sensor link up to equip from Sensor prop up’╝īadjust the conjunction device makes weigh sensor to keep the verticality’╝īthe assurance is whole to weigh the realization of the accuracyŃĆé)

The stability of the system composed of vertical and horizontal two limit system’╝īone end of the protection device is fixed on the main girder’╝īat the other end is fixed on the frameŃĆéThrough the adjustable nut’╝īalso can adjust the track width and the size of the rail gap.

The iron cover plank of the machine equipments has the protection function.

Weigh Sensor Part

Weighing sensor is a key part of the weighing system’╝īthis device adopts digital sensors’╝īhas the features of high precision and good technical performance’╝īfor the weighing accuracy of the whole system has played a important role in guarantee.

The machine install, adjust’╝ībreakdown maintenance.

The machine Install

The work condition of the machine gearing and prepare the work.

The pit of the machine equipments’╝īboth ends foundation’╝īthe control room completion of work’╝īand through check each part meets the homologous technique provisionŃĆéHaving nothing to do with equipments the sundries already clearance.

The basal both ends has already had the condition of build the rail.

The power supply of the spot has already connect.

Theproduct that examination delivers the spot packs the piece and packs well-found and intact’╝ī have no damage.

The crane equipments( load 30t) and worker has already ready to

The electric welding machine’╝īsolderer ready to

Install the machine and link up the system.

According to the request adjustment steel rail elevationŃĆügaugeŃĆürail clearance of the technique document and the diagram paper.

The adjustment sensor to link up the system’╝īmake sensor perpendicularity in the horizontal plane’╝īsensor with armor plate adjustment height’╝īmake each sensor even be subjected to the strength.

Adjust the vertical and horizontal limit system according to the technical requirement

The adjustment pulls the pole to link up the position’╝ītight nut

Install to control the instrument

Sensor line connects to go in junction box’╝īthe total cable wear into the steel pipe to lead into the control room to combine with the instrument of correspond the plug weldingŃĆé’╝ē

b.Install the instrument’╝īthe computer software’╝īthe instrument connects the groundŃĆé’╝ē

cŃĆü’╝łCheck each part after install without any error then connect the power’╝īprepare to adjustŃĆé’╝ē

(The equipments adjusts to try

(Adjust the work condition for try and prepare the work

(The machine part and sensor to link up the system to have already install to complete

(The weight manifestation controls the instrument to have already install to complete

(The orbit circuit has already spread good’╝īand connect all )

’╝łPrepare five carriages’╝īfour vehicles load carriage’╝īan empty carriage ’╝ē

Repeatability and direction error of debugging’╝ē

’╝łLocomotive traction five carriages’╝īagain and again through the device’╝īRecord every time weighing data, compared to the same direction data repeatability, different direction data error value, and then adjust, make the adjustment direction of the same data error to a minimum, different direction of the data error adjustment to a minimumŃĆé)

(The maintenance maintain)

(The machine maintenance)

(The periodical check steel rail elevationŃĆügaugeŃĆütrack sew medium whether be placed in the normal appearance’╝īthere is excrescent circumstance’╝īplease adjust in timeŃĆé)

(Periodical the check limits and each conjunctions part’╝īkeep screw from loosen to moveŃĆé)

(Automatic rail weighbridge of buildingprojects)

(The foundation construction at the request of press relevant technique and the equipments install to request to carry on’╝īthe equipments pit presses manufactory the size and the technique conditions for provides to construct)

(The Automatic rail weighbridge covers the size as follows diagram):