- You are here:

- Home >

- Products >

- Truck Scale

AVS Truck Intelligent Weighing Management System

Unmanned Weighbridge Systems

SILVER LAKE Unattended Truck Weighing System

R

For concrete plant, there are a lot of trucks with cargo entering and existing. That means truck stopping, registering and weighing need to be handled. If all the work is done by operator manually,that not only takes lots of time, but also leads to high error-rate.Besides, man cheatings will easily occur, and which results in huge economic loses. The ŌĆ£AVS truck Intelligent Weighing SystemŌĆØ,developed by SIVLER LAKE, combines the technologies of IC card identification, electronic truck scale, communication, auto-control, data base, and computer networking. In the weighing monitoring area, the AVS system collects the real-time IC card data of passing trucks, and combines the information of weighing area, truck, cargo,and weights together to monitoring center by computer networking,then greatly improves the automated management of enterprise.

The AVS system is designed based on shortening weighing time,improving efficiency, and ensuring the weighing fairness. It is ainly used for automatically collecting weights of trucks,monitoring truck weighing, inputting and reading of IC card data,automatically permitting truckŌĆÖs leaving after weighing, and so on.

Silverlake weighing is a well acclaimed China weighbridge & truck scale manufacturer, we offer our clients amazing deals on vehicle weighing system and solutions.Talk to us!

- Overview

- Specifications

- Accessories

- Literature

3. Details of AVS truck intelligent weighing system

3.1 Digital weighbridge subsidiary system

Since establishment, Kejie has been always engaging in design,manufacture and supply of the toughest weighbridge in China.Kejie SCS-M modular weighbridge adopts completely new structure design from Europe, outstanding rust protection processes, and high quality electric spare parts. It offers faster installation, higher rigidity, greater reliability, higher accuracy, and much easier maintenance than weighbridges from other Chinese suppliers. Besides, our weighbridge solves the poor rust protection problem existing in other suppliersŌĆÖ weighbridges. The weighbridge mainly includes steel platform, load cells, and weighing indicator.

3.1.1 The steel platform is real modular design. Full diamond top plate ensures outstanding anti-slip performance. High ridigity and heavy duty platform can handle up 1 million weighments, the safe overload of which is 170%FS. The structure is specially designed as per the dimension of container, so it is very easy to be delivered by boxcar or container. This platform is fast to install, even in restricted sites, like only forklift available, it takes very short time to finish installation. Removable section covers on the platform allow convenient access for maintenance and service.

3.1.2 C16i digital load cells are from German company ŌĆ£HBMŌĆØ.HBM is the worldŌĆÖs most famous load cell supplier. The HBMŌĆÖs quality is highly approved by numerous customers all over the world.

3.1.3 Digital weighing indicator is from YAOHUA. Shanghai Yaohua Weighing System Co., Ltd, is the largest company of researching, manufacturing and marketing weighing indicators in China. During the 18 years since the establishment, YAOHUA has formed firm alliances and developed steadily. On the basis of solid technology and primary strength and experience in this field, YAOHUA become the leading weighing instruments supplier in China.

For details of weighbridge subsidiary system, please refer to our presentation file of Weighbridge System.

3.2 Photo-electric sensing subsidiary system

The function of photo-electric sensing subsidiary system is to judge the complete locating of truck on weighbridge. The imcomplete on-scale is unacceptable for weighing. Because it will lead to the less and more of cargo net weight, which will result in huge economic loses. By using SICK VS/VE18 4P3112 photoelectric sensors, we can avoid the imcomplete on-scale.

When truck is not passing weighbridge, the photoelectric sensors are in the status of connecting. During truck passing onto the weighbridge, the entrance photoelectric sensors are cut off. When truck is on the weighbridge, the entrance photoelectric sensors are connected again. As to the other side exit photoelectric sensors, they are always connected. Then we can judge that the truck is already completely on the weighbridge. Therefore, the weighing can be started.

The photoelectric sensors we use are SICK VS/VE18 4P3112 (German brand), the world most famous and high quality photoelectric sensor supplier.

3.3 Image snapshot and video monitoring subsidiary system

This subsidiary system can avoid man cheating during weighing.There are two types: one is independent video monitoring system;the other is monitoring system combined together with weighing management software.

According to customerŌĆÖs request, we recommend to select solution two: monitoring system combined with weighing management software.

This system developed by ŌĆ£KejieŌĆØ can not only display video at real time, but also save snapshot picture. When truck enters the weighbridge, the cameras are getting ready for taking images. After the photoelectric sensors judge the truck is completely on the scale, computer will start the camera to take pictures of front and back of the truck. Then these two pictures will be sent into computer one after another, then computer will compress and save the pictures.That is very convenient for management.

Cameras we used are waterproof and infrared camera supplied by Xiangfei, one of the most famous camera manufacturers in China.

3.4 IC card automatic identification subsidiary system

IC card automatic management system includes computer, IC card identification devices (IC card and reader-writer). IC card reader-writer box is installed near the weighbridge, where drivers are easy to reach in the truck. During weighing, driver swipes the IC card in the truck, then the computer in the weigh house can read

the information in the IC card.

(1). Spare parts of IC card:

l _ Semiconductor chip

l _ Semiconductor chip is a super huge integrated circuit

produced by special technics, which includes memory,

decoding circuit, port drive circuit, logic encrypt steering

circuit, and microprocessor.

l _ Electrode mebrane

l _ Plastic uropatagia

(2). Features of IC card:

l _ Huge memory capacity: can reach almost a hundred thousand bytes.

l _ Strong security: logic decoding control is added; before using,password authentification needs to be handled first, only when it is correct, the IC card can send correct respone signal, then next procedure can be done.

l _ Can be used off-line(without networking)

l _ Outstanding anti-jamming

l _ Long life-span: can be written and read for a hundred thousand times

3.4.2 IC card system

(1) IC card memory data definition (temporary) Before confirm of truck scale system, the IC card memory data is defined temporarily as follows:

All the information saved in the card will be saved into the data base. In the data base, the card userŌĆÖs company and photo can be saved as well.

(2) IC card issuing system

The system uses special card issuer to input key and data information. Meanwhile, system saves the relevant data information into the data base.

3.5 LED information directing subsidiary system The large display is strip screen, one color, and rolling screen. It has 12 characters, each character with height of 16cm, outdoor design. Normal temperature and low temperature power modules are optional.

l _ Up-rolling indicates date, time, and operation notice, simple and correct

l _ Rain-proof design ensure the whole day of stable operation

l _ Modular design is easy to repair, replace

l _ The directing information on the display are mostly: ŌĆ£be on caleŌĆØ, ŌĆ£swipe cardŌĆØ, ŌĆ£swiping doneŌĆØ, ŌĆ£be off scaleŌĆØ, and so on.

3.6 Traffic light and barrier control subsidiary system

3.6.1 Function descriptions:

Traffic light and barrier control system, via receiving sequential control instruction,controls the changing of traffic lights and up and down of barrier, which efficiently directs the trucks to leave weighbridge.

3.7 Voice instruction subsidiary system

Functions of BC-2 multi-purpose annunciator: alarming;

continuously adjustable volume.

Technical data:

3.8 Weighing software subsidiary system

3.8.1 Weighing management software

This software adopts the C/S (customer/server) enhanced mode. The conventional C/S mode connects only 1 data base. And our system uses LAN double data base mode,which ensures the weighing can still be handled when network database connecting failed. After network regained, system will automatically uploading the data to the server. In order to avoid the collision between record codes after internet outages and connection, system adopts the weight bill distinguishing method, that is,make the weight bill number unique to avoid the data losing for the reason of same bill number. Meanwhile, during revising ŌĆ£User RightsŌĆØ, truck tare weight,and pre-setting information, all the changed data will be renewed to the database, which is convenient for operators and managers.

3.8.2 Switchover of automatic and manual weighing:

User can switch the mode of software from automatic to manual,so when the automatic function cannot be used, the manual mode can be handled to keep the weighing going, which ensures production line smoothly going.

3.8.3 Shortcut code name input function

The cargo name, supplier, and userŌĆÖs company name can be set as codes and saved into the software. During weighing, user can input the shortcut codes to shorten the whole weighing time, and it takes about 30-40 seconds to finish weighing and printout, which greatly improves the operation efficiency. And this function is very useful in big factory, like concrete plant.

3.8.4 Data interfaces

This intelligent software database supports several interfaces,Web Service, XML files, SQL interface table, and network Socket. It is convenient for ERP and MES systems to receive data. Meanwhile, if hardware permits, the software also offers MODBUS

and 4~20mA signal interface, which is easy for DCS system to receive weighbridge data.

3.8.5 Monitoring snapshot

The system adopts high resolution video collector, which can collect interface strait and forwardly. This system is convenient for later hardware upgrading.

The collected images can be selected and viewed as per data,clear and fast.

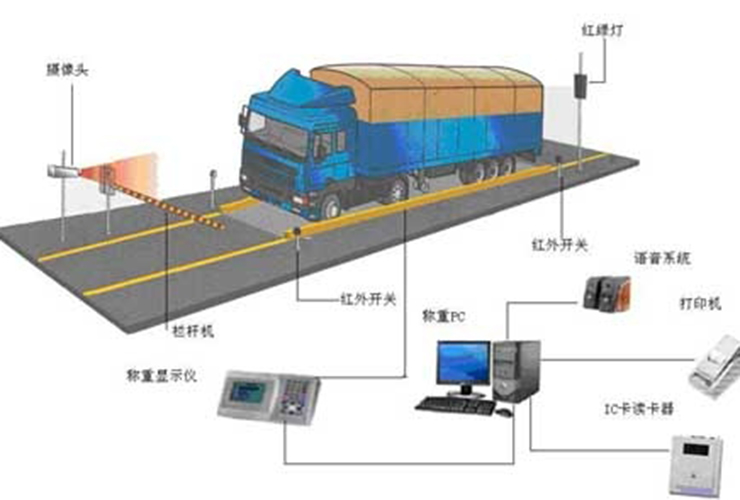

Brief introduction of AVS intelligent system

2.1 Parts of AVS truck intelligent weighing system

The AVS truck intelligent weighing system can be divided into following subsidiary systems:

l _ Digital weighbridge system

l _ Photo-electric sensing system

l _ Image snapshot and video monitoring system

l _ IC card truck automatic identification system

l _ LED information directing system

l _ Traffic light and barrier control system

l _ Voice instruction system

l _ Weighing management software

2.2 AVS truck intelligent weighing system working process

(take entrance weighing for example)

2.2.1 Truck is ready for weighing (Green light on, barrier down)

2.2.2 Truck passes the entrance deductive loop, traffic light turned into red (indicates no entrance of following truck).Meanwhile, the LED display installed at the exit of weighbridge indicates ŌĆ£be on the scaleŌĆØ.

2.2.3 Truck is on the weighbridge. If the truck is completely stopped between two pairs of photoelectric sensors, the LED display indicates ŌĆ£swipe cardŌĆØ. Then driver can stretch hand out of the truck to swipe the IC card on the reader-writer.

2.2.4 When card swiping finished, the Central Control Room detects the truck data, then saves the data. At the same time, the system will direct the camera to make snapshot.

2.2.5 After weighing, LED display indicates ŌĆ£be off the scaleŌĆØ, and the barrier automatically (or manually) moves up accordingly. Then the truck is driven off the weighbridge. When truck completely passes the exit inductive loop, the barrier automatically (or manually) moves down. Meanwhile, the traffic light turns into green.

2.2.6 The weight in the weighing indicator returns to zero. The above is a weighing process. The exit weighing is the same as the entrance weighing.