- You are here:

- Home >

- Products >

- Weighing System

The wheel loader electronic scale is an electronic weighing device installed on the domestic or imported wheel loader to measure the load. It can provide various loading information such as single shovel value and cumulative value of the material being weighed, and print the list. While loading, it can dynamically and synchronously reflect the loading volume, helping customers to complete the weighing operation quickly and at low cost, and accurately load and unload. , to prevent overloading, improve work efficiency, is widely used in factories, mines, railways, ports and other bulk cargo handling operations. Loader electronic scale is the most common name for loader industrial weighing equipment in the industrial industry, also known as loader scale, loader scale, forklift scale, forklift electronic scale and so on.

The loader electronic scale is a kind of loader weighing equipment, which is integrated with the mechanical control part of the loader and realizes weighing during the loader operation. It realizes the weighing by converting the hydraulic pressure into the weight of the load in the bucket by monitoring the predetermined weighing position with a proximity switch. It has two different working modes: target mode and accumulation mode. According to the operator's choice, the load can be automatically accumulated or deducted from the target set value.

The Wheel loader electronic scale enables the loader to automatically weigh the material while loading it. It is suitable for automatic weighing and measurement of loaders (including forklifts), overload protection, workload management, etc. It can weigh coal or coke, non-ferrous ore, earthwork, granite or marble, sand, gravel bricks, industrial and civil waste, excavation materials and construction additives. Application places: wheel loaders such as mines, stations, ports, docks, factories, freight yards, etc.

SILVERKAKE wheel loader scales provide onboard weighing for seamless use, advanced throughput, and enhanced efficiency. SILVER LAKE Scale is an industry leader in heavy-duty weighing systems for large hauling vehicles like wheel loaders. Equipped with an easy-to-use digital readout display installed in the wheel loader cab, our onboard loader scales provide the ultimate in convenience, accuracy, and dependability without needed frequent calibration.

- Overview

- Specifications

- Accessories

- Literature

The wheel loader scale is generally divided into two parts, the signal acquisition part and the signal processing and display part. The signal acquisition part is generally realized by sensors or transmitters, and the accuracy of signal acquisition is very important to the weighing accuracy of the loader.

Wheel Loader Weighing System

1. Static weighing system

It is often used for the modification of existing loaders or forklifts. Since there is no appropriate weighing equipment on site, and the user needs to measure for trade settlement, in view of the user's demand for modification costs, the static measurement method is usually selected. Can be used exclusively for ingredients.

The static weighing equipment consists of: pressure sensor (1 or 2, depending on the accuracy requirements) + ordinary weighing display instrument (optional printer if necessary) + installation accessories (pressure pipe or process interface, etc.).

General characteristics of static weighing:

1) When weighing each time, the position of the weighing bucket is required to be consistent to ensure the accuracy of the weighing, thus affecting the weighing efficiency;

2) The equipment has fewer functions, and many tasks need manual assistance, such as recording, calculation, etc.;

3) It is suitable for short-term workplaces and does not require a large amount of data processing;

4) Low cost, suitable for some self-employed units or small units;

5) There are few parameters involved, and the installation and debugging are more convenient.

2. Dynamic weighing system

For the loading measurement of large units such as stations, ports, and mines, a dynamic weighing system should be selected to meet the needs of rapid, continuous measurement and large-scale data management.

The dynamic measurement and weighing equipment mainly includes: pressure sensor (2 pieces) + dynamic control instrument (with printing function) + installation accessories.

The main functional characteristics of dynamic weighing equipment:

1) Cumulative loading, weight setting, display and overweight alarm functions;

2) Single bucket weight weighing, accumulation and display functions;

3) The truck model selection or input function, the truck number entry function;

4) Input function of operator, loader number and loading station code;

5) Operation time (year, month, day, hour, minute) recording function;

6) Basic job data storage, printing and query functions;

7) Adopt dynamic sampling and fuzzy algorithm to realize dynamic calibration and dynamic weighing, no need to stop the bucket, and automatic weighing during the lifting process;

8) Use the loader power supply for power supply.

9) Using dual hydraulic sensors and high-precision A/D converter, the accuracy is higher.

10) Automatic zero setting or manual zero setting can be set.

System Configuration

u 1 Weighing indicator with thermal printer.

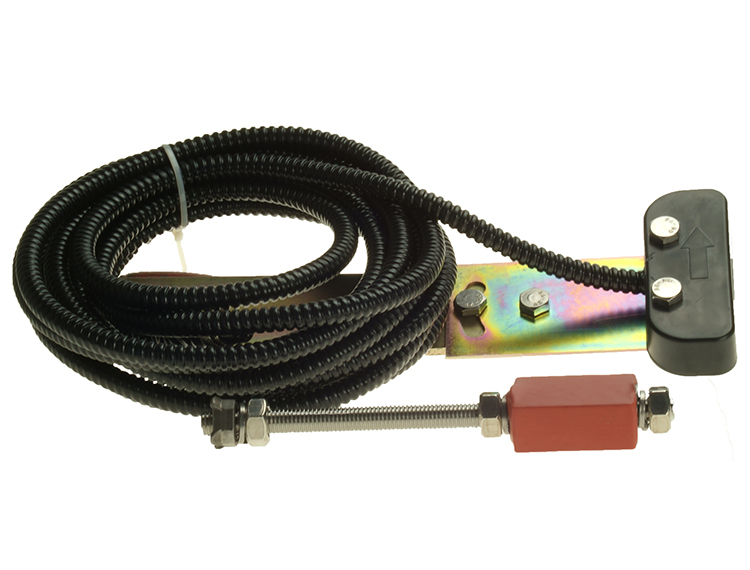

u 1 Position sensor.

u 2 Oil pressure sensors.

u 2 Plate type three-way joints.

u 1 Mounting fitting.

System Accuracy

Accuracy Grade: III.

Verification Accuracy of Weighing Indicator: 0.02%.

Accuracy of Single-Bucket-Weight: 0.5%~1.0%.

Accuracy of Totalized Loading Weight: 1.0%.

Wheel laoder scale Main Features:

EMC design with high anti-jamming capability, suitable for industrial environment. DC24V power input circuit with reverse polarity protection function.

32-bit ARM CPU with 72MHz & high arithmetic speed.

Dust-proof stainless steel shell with protection level IP65.

640├Ś480 TFT color display screen for English character display.

The display informations of Bucket Lifting/Declining state, Single-bucket-loading-weight,

Totalized Loading Weight, Positive/Negative Deviation Value, Alarm state, Date/Time and other auxiliary data are used for judging if Single-bucket-loading-weight is valid and the loading process should be stopped.

20-key English keypad with controllable backlight.

Number and English Alphabet can be inputted.

The informations of User Name, Truck No., Goods No. and Operator No. can be inputted.

Upper/Lower Limit of Single-bucket-loading-weight, Setpoint of Totalized Loading Weight and

Date/Time can be set.

Operating Time, Single-bucket-loading-weight, Totalized Loading Weight and Alarm