- You are here:

- Home >

- Products >

- Floor Scale

Explosion-proof platform scales with copper wheels

Use explosion-proof platform scales to weigh flammable product drums

Always keep safety in mind when you are dealing with dangerous and flammable substances. In addition, when purchasing equipment for such substances, it is important to consider using only explosion-proof machinery.

Why You Need An Explosion-Proof Industrial Platform Scale?

Explosion-proof means that the machine or equipment can safely contain sparks and prevent explosion if sparks are generated. Explosion-proof machinery can avoid dangerous chemical fires and explosions. Another term used to describe such devices is "intrinsically safe". This means that the machines involved cannot produce enough energy to even cause sparks or flames.

The demand for explosion-proof industrial platform scales stems from their safety protection and technical support in specific high-risk environments, which is mainly reflected in the following aspects:

1. Safety protection needs

ŌĆīPreventing explosion risksŌĆī

In the chemical, petroleum and other industries, the weighing process of flammable and explosive substances (such as ethanol, benzene, etc.) is prone to explosions due to circuit sparks or static electricity. Explosion-proof industrial platform scales effectively isolate explosion sources through isolation design, fully sealed housing and explosion-proof components (such as Ex d ia IIB T4 Gb certification) to avoid sparks or arcs in dangerous environmentsŌĆī12.

ŌĆīIntrinsically safe designŌĆī

Its circuit system will not ignite explosive mixtures in normal or faulty conditions. Even if it is overweight or operating abnormally, it can trigger an alarm or stop working through the automatic detection function to reduce the risk of accidentsŌĆī35. 2. Industry application scenarios

ŌĆīHigh-risk industrial fieldsŌĆī

ŌĆīChemical industryŌĆī: Ensure formula accuracy and operation safety when weighing flammable and explosive raw materials (such as ether)ŌĆī

ŌĆīPetroleum and metallurgical industryŌĆī: Used for weighing fuel oil and high-temperature metal materials, adapting to high-pressure and highly corrosive environmentsŌĆī

ŌĆīPharmaceutical and food industryŌĆī: Complete raw material measurement under strict safety standards to ensure product qualityŌĆī

ŌĆīAdaptability to complex environmentsŌĆī

The scale body is made of stainless steel or carbon steel spray-coated material, which has the characteristics of corrosion resistance, rust resistance and wear resistance, and can operate stably under harsh conditions such as humidity and dustŌĆī24.

3. Functional and technical advantages

ŌĆīHigh precision and stabilityŌĆī

Equipped with high-sensitivity sensors and digital signal processing technology, the weighing accuracy can reach 1/10000 to ensure measurement accuracyŌĆī.

ŌĆīOperation convenienceŌĆī

Supports multi-language display, automatic peeling, cumulative weighing and other functions, and the keyboard design is intuitive to reduce the operating thresholdŌĆī.

ŌĆīExtended functionsŌĆī

Some models have advanced functions such as weight detection alarm, data printing, dynamic weighing, etc. to meet diverse industrial needsŌĆī. In summary, explosion-proof industrial platform scales have solved the potential safety hazards of weighing in high-risk environments through technical design and function optimization, while improving efficiency and data reliability, becoming an essential tool for industries such as chemical and petroleum.

- Overview

- Specifications

- Accessories

- Literature

Explosion-proof platform scales with copper wheels

1. Intrinsic safety and explosion-proof performance of explosion-proof platform scales

ŌĆīExplosion-proof technology meets standardsŌĆī

Adopting explosion-proof design that meets international standards (such as Ex d ia IIB T4 Gb, Ex ia IIC T4 Ga), through fully sealed housing, explosion-proof components and spark-free circuit system, effectively isolates potential risks in flammable and explosive environmentsŌĆī.

2. High precision and stability

ŌĆīPrecision sensing technologyŌĆī

Adopting high-sensitivity sensors (such as HBM C16 series) and digital signal processing technology, the weighing accuracy can reach 0.01KG, and the resolution of some equipment is as high as one hundred thousandthŌĆī23.

ŌĆīAnti-interference designŌĆī

Through multi-sensor redundant layout and dynamic filtering algorithm, more than 90% of environmental vibration or electromagnetic interference is eliminated to ensure stable and reliable data; built-in temperature compensation module (such as PT1000 sensor) automatically corrects errors caused by temperature fluctuationsŌĆī. Ensures high precision and reliability of explosion-proof platform scales

3. Durable materials and protective structures

ŌĆīCorrosion-resistant materialsŌĆī

The scale body of the explosion-proof platform scale is made of 304 stainless steel or carbon steel spray-coated, with a surface that is corrosion-resistant and rust-resistant, suitable for humid, dusty or chemically corrosive environmentsŌĆī23.

ŌĆīStrengthening structural designŌĆī

The U-shaped steel frame and double-layer sensor bracket improve the load-bearing capacity, which can carry a weight exceeding 150% of the nominal range and extend the service life of the equipmentŌĆī15.

4. Multi-function and intelligent operation

ŌĆīDiverse function integrationŌĆī

Supports weight/unit switching (kg/g/IB/OZ), automatic peeling, cumulative measurement, as well as upper and lower limit alarms, data printing and other extended functions to meet the needs of complex industrial scenariosŌĆī12. ŌĆīIntelligent UpgradeŌĆī

Some models integrate 5G communication modules and edge computing capabilities, support real-time data transmission, AI violation identification (such as abnormal cargo stacking), and seamlessly connect with the production management system (DCS)ŌĆī

V. Wide Applicability

ŌĆīAdaptation to High-risk IndustriesŌĆī

Designed for explosion-risk industries such as chemical (raw material weighing), petroleum (fuel metering), and pharmaceutical (sterile workshops), meeting strict safety certification requirements such as ATEX and IECExŌĆī1

ŌĆīAdaptation to Harsh EnvironmentsŌĆī

The protection level reaches IP69K, and it can operate stably in the temperature range of -10Ōäā to 40Ōäā and under high pressure and high humidity conditions to ensure all-weather operation needsŌĆī

Changzhou silver lake Electronic Technology Group Co., Ltd. is a high-quality manufacturer of explosion-proof platform scales in China

Explosion-proof platform scales with copper wheels

EX SILIVER LAKE share load cell 2T,3T,5T

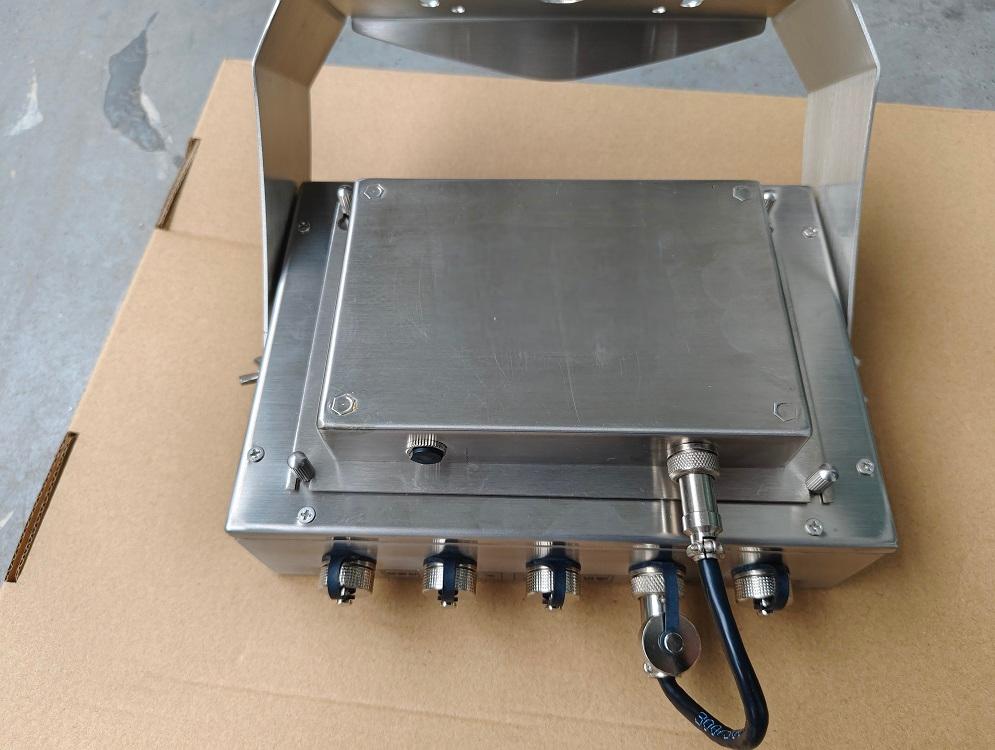

Explosion-proof weighing instrument

The standard sizes of explosion-proof platform scales include 1X1M, 1.2X1.2M, 1.5X1.5M

. These sizes are very common in the field of explosion-proof platform scales and are suitable for different weighing needs.

In addition, the size of the explosion-proof platform scale can also be customized according to specific needs. For example, some explosion-proof platform scales have a table size of 800*800mm, which can also be customized according to the actual needs of customers. Common recommended sizes include 1X1M, 1.2X1.2M, and 1.5X1.5M

The design features of explosion-proof platform scales include:

ŌĆīMaterialŌĆī: Usually made of stainless steel, with explosion-proof grade Ex ib II CT3/CT4ŌĆī

ŌĆīDisplayŌĆī: 20mm LCD display with backlightŌĆī

ŌĆīPowerŌĆī: Support AC/DC intrinsically safe power supply and intrinsically safe explosion-proof batteryŌĆī

ŌĆīUse environmentŌĆī: Suitable for -10~40Ōäā, humidity Ōēż90% environmentŌĆī

ŌĆīOutput signalŌĆī: Support RS232, RS485 and 4~20mA analog outputŌĆī